Meta Description:

Discover the world of power relays and their uses in various applications. This comprehensive guide covers everything from how power relays work to their use in automotive and industrial control systems.

Introduction:

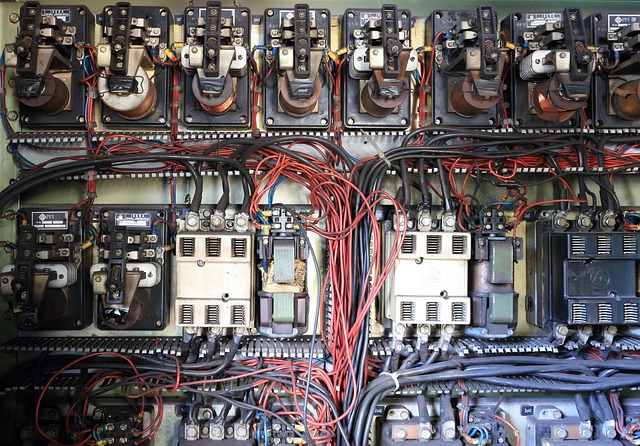

Relays are electrical switches that use an electromagnet to close or open a circuit, allowing for control of high-power electrical devices. Power relays are designed to handle large amounts of power and are commonly used in various applications.

Power relays are essential components in many electrical systems, providing a safe and reliable way to control high-power electrical devices. They serve as a switch that can be triggered by a small electrical signal, allowing the control of high-power loads that would otherwise be too dangerous or impractical to control directly.

Understanding power relays and their applications are crucial to successful electrical design and maintenance, whether you’re working in automotive, industrial control systems, or renewable energy systems.

Let’s dive into the world of power relays and discover how they are used to safely and reliably control high-power electrical devices.

Types of Power Relays

Several types of relays include electromagnetic, solid-state, and hybrid relays. Each type of relay has unique features and benefits, making them suitable for different applications.

Electromagnetic Relays

These are the most common power relays and use an electromagnet to control a switch. They are reliable and cost-effective, making them a popular choice for industrial applications.

Solid-State Relays

These relays use semiconductor components to control the switch rather than an electromagnet. They are fast-acting and have no moving parts, making them ideal for high-frequency applications.

Hybrid Relays

These relays combine the best of both electromagnetic and solid-state relays. They are fast-acting and have no moving parts, but they also offer the reliability of electromagnetic relays.

Reed Relays

Reed relays are electromechanical relays that use a magnetic reed switch to control power. The reed switch consists of a pair of thin metal reeds that are sealed within a glass envelope.

When a magnetic field is applied to the reeds, they attract each other and close the switch, allowing current to flow. When the magnetic field is removed, the reeds return to their original position, opening the switch and breaking the circuit.

Reed relays are widely used in various applications, including telecommunications, automotive, and industrial control systems, due to their compact size, fast switching speed, and low cost.

Time Delay Relays

Time delay relays control power for a specified amount of time. They allow the switching of a high-power load after a pre-determined time interval has elapsed. This can be useful in applications such as lighting control, HVAC systems, and industrial process control, where it is necessary to control power for a specific time.

Time delay relays can be set to activate after a specified time interval has elapsed, or they can be set to activate immediately and then deactivate after a specified time interval has elapsed.

Overload Relays

Overload relays protect electrical systems from damage caused by excessive current. They are typically used in applications such as motors, transformers, and other electrical equipment where overloading could cause damage to the equipment or create a safety hazard.

Overload relays work by detecting excessive current and breaking the circuit if the current exceeds a specified level. This can help to prevent damage to electrical equipment and prevent safety hazards, making them an important component in many electrical systems.

Latching Relays

Latching relays maintain a switch position after the trigger signal is removed. This allows the switch to remain in a particular position without needing a continuous electrical signal. Latching relays are commonly used in applications such as lighting control, HVAC systems, and industrial process control, where it is necessary to maintain a switch position for an extended period.

A small electrical signal can trigger latching relays, and once triggered; they maintain the switch position until they are triggered again to change the position.

Mechanical Relays

Mechanical relays use mechanical components, such as levers and gears, to switch power. These relays work by mechanically moving a switch to close or open the circuit, allowing or blocking the current flow.

Mechanical relays are widely used in automotive, industrial control, and renewable energy systems for their simplicity, reliability, and durability.

Mercury-Wetted Relays

Mercury-wetted relays are electromechanical relays that use mercury to switch power. The mercury switch consists of a pair of metal contacts submerged in a pool of mercury. When a current is applied to the contacts, the mercury is ionized and conducts electricity, allowing the current to flow and closing the switch.

Mercury-wetted relays are typically used in high-power switching applications due to their fast switching speed and high current carrying capacity.

Thermal Overload Protection Relays

Thermal overload relays or heat-operated relay protect electrical systems from damage caused by excessive temperature. They detect excessive temperature and break the circuit if it exceeds a specified level.

This can help to prevent damage to electrical equipment and prevent safety hazards, making them an important component in many electrical systems. Thermal overload relays are commonly used in motors, transformers, and other electrical equipment applications.

Applications of Power Relays

Power relays are used in a variety of applications, including:

Automotive: Power relays are used in automotive applications to control high-power electrical devices such as headlights, horns, and electric motors.

HVAC: In heating, ventilation, and air conditioning (HVAC) systems, power relays are used to control the operation of compressors and fans.

Industrial: In industrial applications, power relays control large motors, pumps, and other high-power electrical devices.

Medical: In medical equipment, power relays control high-power electrical devices such as X-ray and MRI machines.

Energy Management: Power relays are used in energy management systems to control the flow of electricity and prevent power surges.

Choosing the Right Power Relay for Your Application

Several factors should be considered when choosing a power relay for a specific application, including the voltage and current requirements, operating temperature, and response time. Choosing a suitable relay for the specific application is important to ensure that it operates safely and efficiently.

Advantages of Power Relays

There are several advantages of using power relays in various applications, including:

Safety

Power relays provide a safe way to control high-power electrical devices by isolating the control circuit from the load circuit. This reduces the risk of electrical shock and other hazards.

Efficiency

Power relays are fast-acting and allow precise control of high-power electrical devices, improving system efficiency and reducing energy consumption.

Reliability

Power relays are designed to handle large amounts of power and are typically more reliable than other switches. This makes them a popular choice for industrial applications where downtime can be costly.

Cost-effectiveness

Power relays are relatively inexpensive and offer a cost-effective solution for controlling high-power electrical devices in various applications.

Maintenance and Repair of Power Relays

It is important to ensure that power relay operates safely and efficiently and perform regular maintenance and repair as needed. This may include cleaning and lubricating the moving parts, checking the contacts for wear and damage, and testing the relay to ensure it is functioning properly.

In the event of a failure, it is important to replace the power relay as soon as possible to avoid further damage to the system and to restore proper operation. When replacing a power relay, choosing a replacement compatible with the specific application that meets the voltage and current requirements is important.

What is PCM Power Relay?

PCM (Power Control Module) power relays are specialized relays used in automotive applications to control high-power electrical devices. They are typically integrated into the vehicle’s power control module and are responsible for controlling the operation of devices such as the headlights, horn, and electric motors.

PCM power relays are designed to handle high voltages and currents and are typically more rugged and durable than other relays. They are also designed to meet the specific requirements of automotive applications, including environmental resistance, vibration resistance, and high reliability.

What is a Power Relay Module?

A power relay module is a device that contains multiple power relays in a single unit. This allows for the control of multiple high-power electrical devices from a single location, simplifying the wiring and control of the system.

Power relay modules typically include an interface for controlling the relays, such as a microcontroller or control circuit. They may include additional features, such as overload protection relays, monitoring circuits, and diagnostic features.

Power relay modules are commonly used in industrial and commercial applications where multiple high-power electrical devices must be controlled from a single location.

What is Reverse Power Relay?

A reverse power relay is a device to detect and protects against reverse power flow in electrical systems. Reverse power flow can occur when the flow of electricity is in the opposite direction of its intended flow, which can cause damage to equipment and other electrical components.

Reverse power relays detect reverse power flow by monitoring the direction of current flow in the system. If reverse power flow is detected, the relay opens the circuit, preventing further damage to the system.

Reverse power relays are commonly used in renewable energy systems, such as solar photovoltaic and wind turbine systems, to protect against reverse power flow when the system is not generating enough energy to meet the demand. They are also used in other electrical systems where reverse power flow is a potential hazard, such as backup power systems and uninterruptible power supplies (UPS).

What is a Power Relay?

A power relay is an electrically-operated switch used to control high-power electrical devices. It consists of a coil, contacts, and a mechanical armature and is typically used to switch high-current or high-voltage loads in various applications.

The coil of a power relay is energized by a low-power control signal, which causes the armature to move and close the contacts, completing the circuit and allowing electrical current to flow to the load. When the control signal is turned off, the armature returns to its original position, opening the contacts and breaking the circuit.

Power relays are designed to handle large amounts of power, making them essential in many industrial and commercial applications where high-power electrical devices must be controlled.

How does an Electromechanical Relay Coil Work?

An electromechanical relay works by using an electromagnet to control a mechanical switch. It consists of three main components: the coil, the armature, and the contacts.

The relay’s coil is an electromagnet energized by a low-power control signal, typically from a microcontroller or control circuit breaker. When the coil is energized, it creates a magnetic field that attracts the armature, a metal lever attached to the switch contacts.

The relay contacts are typically made of metal and are designed to handle high currents and voltages. When the armature is attracted to the coil, it closes the switch contacts, completing the circuit and allowing electrical current to flow to the load.

When the control signal is turned off, the magnetic field in the coil collapses, causing the armature to return to its original position and open the switch contacts, breaking the circuit.

How do Solid-State Relays (SSR) Work?

A solid-state relay (SSR) is a type of switch that uses semiconductor technology instead of a mechanical switch to control the flow of electrical current. It consists of a driver circuit, an optoisolator, and a power MOSFET.

The driver circuit in the SSR is responsible for converting the low-power control signal into a high-power signal that can be used to switch the power MOSFET.

The optoisolator isolates the low-power control circuit from the high-power switching circuit, ensuring electrical safety. The power MOSFET in the SSR is a switch that uses a flow of electrical current to control the flow of electrical current in the load.

When the control signal is applied to the driver circuit, it triggers the power MOSFET, allowing electrical current to flow to the load. When the control signal is turned off, the power MOSFET is turned off, breaking the circuit and stopping the flow of electrical current.

Uses and Applications of Power Relays

Power relays are used in a wide range of applications, including:

Automotive Systems: Power relays are used in automotive electrical systems to control high-power devices such as headlights, horns, electric motors, and fuel pumps.

Industrial Control Systems: Power relays are used in industrial control systems to control motors, pumps, and other high-power electrical devices in manufacturing, process control, and material handling applications.

Renewable Energy Systems: Power relays are used in renewable energy systems, such as wind turbines and solar photovoltaic systems, to control high-power devices and protect against reverse power flow.

Backup Power Systems: Power relays are used in backup power systems, such as uninterruptible power supplies (UPS), to control power transfer from the primary source to the backup source.

HVAC Systems: Power relays are used in heating, ventilation, and air conditioning (HVAC) systems to control fans, compressors, and other high-power electrical devices.

Lighting Control Systems: Power relays are used in lighting control systems to switch high-power lighting loads on and off.

Security Systems: Power relays are used in security systems, such as alarm systems, to control high-power electrical devices such as sirens and strobe lights.

Conclusion:

This comprehensive guide has explored the world of power relays and their uses in various applications. We have covered everything from the basics of how power relays work, including electromechanical and solid-state relays, to their use in automotive systems, industrial control systems, renewable energy systems, backup power systems, HVAC systems, lighting control systems, and security systems.

With this information, you now understand power relays and their crucial role in safely and reliably controlling high-power electrical devices.