Meta Description: In this article, we will briefly discuss the tantalum capacitor, its uses, working principle, and applications where it is used.

Introduction

A tantalum capacitor is a capacitor that uses tantalum as one of its electrodes. Tantalum capacitors are used in various electronic devices, including computers, cell phones, and other portable devices.

They are also used in some military and aerospace applications. They are also used in some medical devices and military and aerospace applications. Tantalum capacitors are generally more expensive than other types, but they have several advantages, including a higher capacitance per unit volume, higher voltage rating, and better stability.

A tantalum capacitor is a capacitor that uses tantalum as one of its electrode materials. Solid Tantalum capacitors are very stable and have a very long lifespan. They are also very small, making them ideal for portable electronic devices.

Tantalum capacitors are more expensive than other types, but their performance and reliability make them worth the extra cost. A tantalum capacitor uses tantalum as its dielectric material. It’s the most common capacitor used today because it has good performance, excellent value, and low cost.

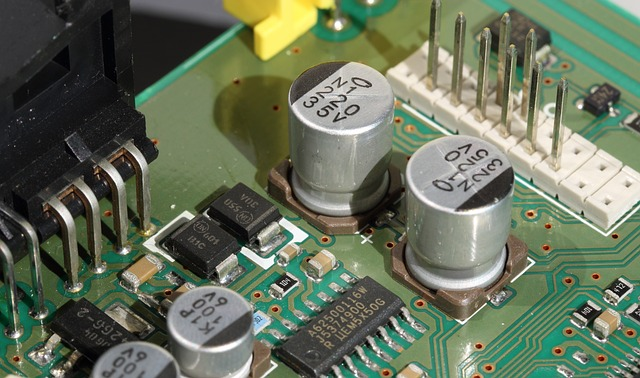

Basic Construction of Tantalum Capacitor

Electrically-conductive properties of tantalum make it suitable for use as an electrode material. They are also called “anode” or “negative electrodes” in electric capacitors because they can hold a significant amount of electricity without being damaged by overvoltage or current spikes.

That makes it an ideal component for high-performance applications such as large-scale storage batteries used by power generation, transportation, communications, and aerospace industries.”

A Tantalum capacitor is made from, as the name suggests, tantalum. Tantalum is a dark blue-grey metal that, in its natural state, is relatively rare in the Earth’s crust. The element of tantalum is a relatively rare metal in the Earth’s crust. It has a metallic luster and appears blue-grey.

Tantalum is an element found in nature, but it must be refined to be used in our modern world. Refining the metal involves heating it until it melts, then allowing the molten material to cool down into its natural state as a solid material which takes time.

Tantalum is one of two transition metals with a high-temperature coefficient of capacitance. This means that it can store more charge than other materials at higher temperatures, which makes it useful for applications like electric motors or computer hard drives where heat buildup may cause damage over time.

Basic Principle of Tantalum capacitor

A tantalum capacitor is a device that utilizes the properties of tantalum metal to achieve high capacitance and low dielectric loss.

The most common application for a tantalum capacitor is in audio equipment, where they are used for their high electrical conductivity and the low voltage drop across their surface area (0.1 m2).

A Tantalum capacitor can be used in other areas, such as radio frequency (RF) circuits. Their low losses allow them to be used over large ranges without sacrificing performance due to current leakage through the dielectric material.

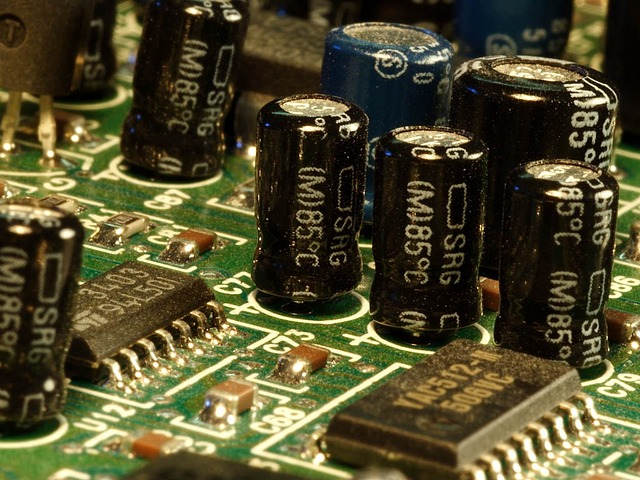

Characteristics of tantalum electrolytic capacitors

Tantalum electrolytic capacitors are used in a wide range of applications. They have the following characteristics:

Working voltage – 100 to +100 volts (V)

Capacitance value 0.1 to 1000 uF

Dielectric strength 2000 V at 20 degrees C

Working Principle of Tantalum Capacitor

Tantalum electrolytic capacitors are polarized devices. The anode, or positive terminal of the capacitor, is connected to a voltage source or ground. The cathode, or negative terminal of the capacitor, is connected to a lamp’s wiring and grounded within your circuit.

To ensure that your capacitor doesn’t short out when you power it up, which could cause damage, you’ll need to ensure that both ends of your device are connected properly with no gaps.

This way, there won’t be any electric current flowing through any part other than what should be happening: current flowing from one side into another through some material like aluminum foil, paper tape, rubber, etc.

Electrical Characteristics of Tantalum Capacitor

A Tantalum capacitor has a very low ESR and ESL compared to other electrolytic capacitors. The high stability of the Tantalum film ensures the long-life expectancy of these capacitors, which can be up to 1000 times longer than that of ceramic capacitors used in analog circuits.

Construction of Tantalum Capacitor

A Tantalum capacitor is made of tantalum powder and other materials. They are layered on each other uniquely to form the desired shape. The surface area of these layers must be large enough to allow electrons to move through it quickly but not too big that they will dissipate too much energy as heat when they pass through it.

Tantalums have very high electrical conductivity (about two times higher than copper). Still, they also have low thermal conductivity, so they don’t transfer heat well from one side to another during operation.

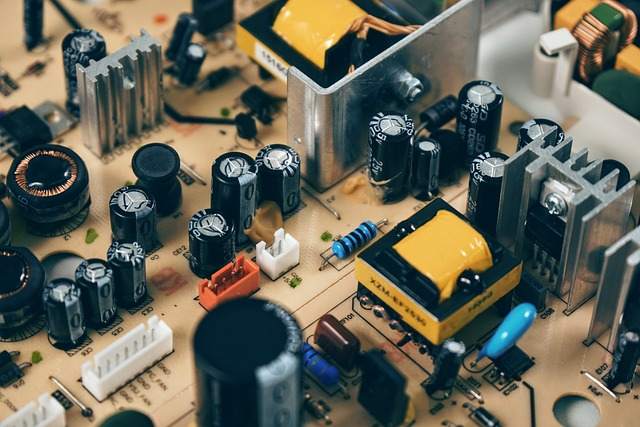

Applications of Tantalum Electrolytic Capacitors

Tantalum electrolytic capacitors are widely used in applications such as portable electronics and computers, cell phones, personal digital assistants (PDAs), radio communications, air and navigation systems, high-end audio amplifiers, industrial surveillance equipment, and medical instruments.

In the field of power electronics, they are used for many purposes, including:

Low voltage switching regulators operate at up to 500 volts DC or fewer voltages. High-voltage power supplies for welding machines or other high-power applications where transient events must be handled with minimal disturbance to the line voltage itself.

These devices can also be found in submersible robots, which protect against water ingress. And Providing enough current availability to function correctly under adverse conditions. Such as those found underwater during submersion events. This design has been beneficial when building autonomous underwater vehicles (AUVs).

Uses of Tantalum Capacitors

Tantalum has many uses outside of electronics; some examples include the following:

Combinational Properties with multiple elements

Like many functional industrial materials, it occurs more commonly combined with other elements. Tantalum is a silvery-white metal that is rather soft and malleable. It has a relatively high melting point of 2,610°C (4,520°F), making it suitable for use in alloys with other metals with lower melting points or is challenging to work with.

Tantalum is also very resistant to corrosion. Its high melting point and corrosion resistance make it ideal for spacecraft components. During launch operations, they will be exposed to harsh environments such as outer space or extreme temperatures on Earth’s surface.

Increasing Battery Life

Only a few metals have a higher density than tantalum. You may have heard of tantalum electrolytic capacitors, but what do they do? A tantalum capacitor is a device that can store energy and release it later. It’s one of the best ways to increase your battery life by keeping your phone charged longer.

A Tantalum capacitor is used in many devices, such as laptops, cars, and phones because they are good at storing large amounts of electricity without getting hot or breaking down over time. There are only two substances with higher densities than tantalum: gold (9) and platinum (38).

Dielectric in a Capacitor

Tantalum can make a very thin oxide layer, acting as a dielectric in a capacitor. The specific properties of tantalum’s oxide layer make it an excellent dielectric material for capacitors.

The tantalum pentoxide (Ta2O5) is a high dielectric material that can be deposited at a high temperature onto tantalum powder of suitable purity to form a dielectric layer on each grain of tantalum powder.

The Ta2O5 film may be grown by chemical vapor deposition (CVD), physical vapor deposition (PVD), or wet chemical methods. It is used in capacitors because it has suitable insulation properties and high dielectric strength.

The anode is formed by pressing into this powder and sintering it into a solid disc or rod.

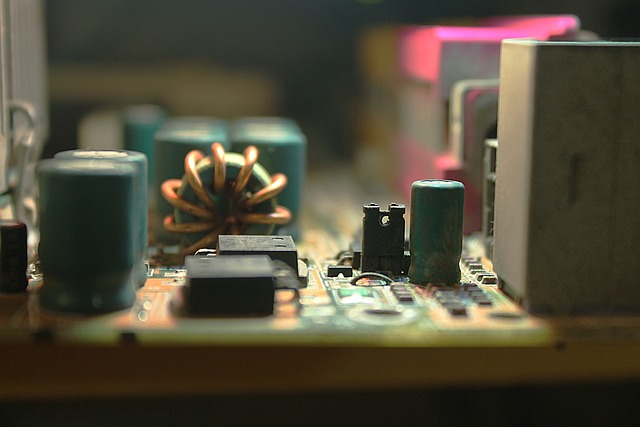

Application in Sintering Process

Sintering is a process that involves heating a material to a high temperature without melting it. This creates dense materials with high strength and hardness, which can be used for many applications. In the case of capacitors, sintered anodes are used because they provide more extraordinary performance than non-sintered ones, although this depends on their composition.

The anode is formed by pressing into this powder and sintering it into a solid disc or rod. When the pressed powder is sintered, it includes around 96% porous solid material.

When the pressed powder is sintered, it forms around 96% porous solid material. This process can make high surface area capacitors ideal for heat dissipation applications.

At this stage, the tantalum electrolytic capacitor has only one electrode and will not yet work, but it is now ready for further processing.

This is a typical step in the fabrication process, where we prepare the tantalum electrolytic capacitor (TEC) for its final operation.

A liquid electrolyte is then vacuum-tightly sealed into a case to cover and impregnate the porous anode material, thus completing the capacitor assembly process.

Good Impedance Frequency

A tantalum capacitor is known for good impedance frequency characteristics, making them ideal for high-frequency applications. Tantalum Electrolytic capacitors are also very stable, meaning they maintain their capacitance value over time.

Protection from Short Circuiting

Tantalum electrolytic capacitors are used to protect against damage caused by short-circuiting. They are also used to help keep the voltage steady in high-voltage systems. Tantalum capacitor comes in a wide range of sizes. From small ones that can be mounted on circuit boards or soldered directly into circuit board traces up to large units that can be used as replacements for entire power supplies or transformers.

Ideal for High-Frequency Applications

A Tantalum capacitor has a low loss values, making them ideal for high-frequency applications such as microwave transformers or resonators.

The main reason why these capacitors have been developed so far is because of their compact size. It makes them very convenient to use in tight spaces where space is limited. Like on printed circuit boards or in portable devices such as mobile phones, laptops, etc.

Highly recommended in Portable Electronics

Tantalum electrolytic capacitors are one of the famous passive components in the electronic world. They are commonly used in many applications because of their merits.

They are widely used in applications such as portable electronics and computers, cell phones, personal digital assistants (PDAs), radio communications, air and navigation systems, high-end audio amplifiers, and industrial surveillance equipment.

High Electrical Conductivity

This capacitor’s main component is tantalum (Ta), which provides high energy density due to its relatively high electrical conductivity. It also has a low thermal coefficient, so it can withstand high-temperature conditions when working under extreme loads without degradation or loss of performance over time.

A tantalum capacitor is a particular type of capacitor that uses the material tantalum. This can be used to store energy in electrical form, which allows it to be used as a power source or amplifier.

High Endurance with excellent stability

Tantalum electrolytic capacitors have been used for years in many applications because they have excellent stability and high Endurance with low losses over time.

In addition, they are also reliable and safe when working correctly because they do not produce harmful materials such as lead sulfide or mercury poisoning. When they fail while being used correctly, this means not breaking apart. Therefore, they are ideal for use within electronic systems requiring high reliability.

Withstand Extreme Temperatures

Tantalum electrolytic capacitors have several advantages over other types of capacitors. These advantages include the ability to withstand extreme temperatures without losing their ability to hold an electrical charge. And their stability under shock conditions such as those experienced during electrical storms and lightning strikes which can damage even strong conductors.

No effect on the current flow.

Tantalum is nonpolarized. So it does not affect the current flow through other components as aluminum electrolytic capacitors do.

This property makes it especially useful in applications where current flows through multiple electronic devices, such as computer servers, which require high levels of reliability and dependability from all components involved.

Conclusion

There are many uses for these incredible materials that allow us to build everything from computers and cell phones to skyscrapers and airplanes today!

Tantalum Capacitor is an essential part of many devices because it prevents excessive current from flowing into sensitive circuits or other components, which can damage them over time.

A Tantalum capacitor carries many applications, including portable electronics like cell phones and personal digital assistants (PDAs), GPS systems, air navigation systems, and medical instruments such as monitors for patients with pacemakers or defibrillators.