Meta Description

Are you in search of an all-inclusive handbook on ceramic capacitors? This guide covers everything about ceramic capacitors’ construction, properties, types, and applications.

Introduction

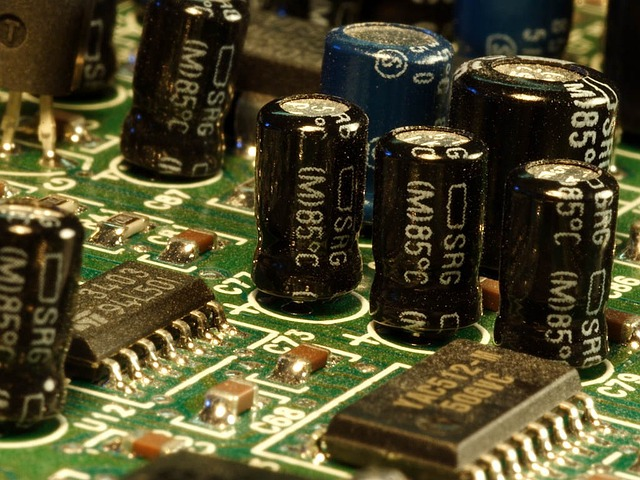

Ceramic capacitors are a fundamental component used in a variety of electronic circuits. With their small size, low cost, and high reliability, they are an essential part of many electronic devices.

They are made by sandwiching a ceramic dielectric material between two metal electrodes, which allows them to store electrical energy. Ceramic capacitors are available in various capacitance values, voltage ratings, and sizes, making them suitable for multiple applications. They are used in everything from consumer electronics to industrial machinery and are essential to many electronic devices.

If you are new to the world of electronics or looking to learn more about ceramic capacitors, you have come to the right place. This guide will cover everything you need about ceramic capacitors, including their construction, properties, types, and applications.

Origin of Ceramic Capacitors

The origin of ceramic capacitors can be traced back to the early 20th century when scientists and engineers explored new ways to improve electronic devices.

The first ceramic capacitors were developed in the 1930s and were made from a mixture of ceramic materials and metal particles. These early ceramic capacitors were limited in their capacity and unreliable, but they were an essential step towards the development of modern ceramic capacitors.

During the 1950s and 1960s, technological advances led to the development of new materials and manufacturing processes that significantly improved the performance and reliability of ceramic capacitors. Today, ceramic capacitors are widely used in electronic devices such as computers, televisions, and mobile phones.

Construction of Ceramic Capacitor

Ceramic capacitors are typically constructed by sandwiching a thin layer of ceramic material between two metal plates, which act as the electrodes of the capacitor.

The metal plates are usually made of silver or palladium, chosen for their high conductivity and resistance to corrosion. The ceramic material, the coupling capacitor’s thickness, the metal plates’ size, and the distance between the plates all contribute to the capacitance.

Properties of Ceramic Capacitor:

The materials used in construction determine the properties and electrical characteristics of ceramic capacitors. Some of the critical properties of ceramic capacitors include the following:

Capacitance

Ceramic capacitors have a high capacitance relative to their size, making them an ideal choice for high-density electronic circuits.

Tolerance

The capacitance of ceramic capacitors can be accurately controlled during manufacturing, resulting in a high level of tolerance and consistency.

Temperature stability

Ceramic capacitors have excellent stability over various temperatures, making them suitable for high-temperature applications.

Frequency stability

Ceramic capacitors have a low loss factor, meaning they have excellent frequency stability and are well-suited for use in high-frequency circuits.

Voltage rating

The voltage rating of ceramic capacitors determines the maximum voltage that the capacitor can withstand without breaking down. High-voltage ceramic capacitors are available for use in high-voltage applications.

Types of Ceramic Capacitors

Ceramic capacitors are a critical component in many resonant circuits used in electronic devices, where they are used to tune the resonant frequency of the circuit. Class 1 ceramic capacitors are ideal for resonant circuits due to their high stability, low losses, and high Q-factor.

Power ceramic capacitors are designed to handle high current and voltage levels, making them suitable for power electronics applications.

Barrier layer capacitors, also known as metal-insulator-metal (MIM) capacitors, are a type of ceramic capacitor that use alternating layers of metal and ceramic material to achieve a high capacitance value.

Multilayer Ceramic Chip Capacitor (MLCCs)

MLCCs are the most common type of ceramic capacitor. They are made by stacking multiple layers of ceramic and metal electrodes on top of each other. The ceramic layers themselves are then connected with metal terminals at each end. MLCCs are available in a wide range of sizes and capacitance values, and they are commonly used in consumer electronics, such as mobile phones and laptops.

High-voltage ceramic capacitors

High-voltage ceramic capacitors are designed to withstand high voltages and are commonly used in power supplies, electronic ballasts, power circuit breakers, and other high-voltage applications.

Ceramic disc capacitors

Ceramic disc capacitors are a type of ceramic capacitor that are commonly used in electronic circuits due to their small size, low cost, and high reliability. They are made by sandwiching a top ceramic layer of dielectric material between two metal electrodes and then encapsulating the assembly in a ceramic disc-shaped body.

The ceramic dielectric material used in ceramic disc capacitors is typically a ceramic material such as barium titanate or titanium dioxide. These materials have a high dielectric constant, which allows for a significant capacitance value in a small volume. The metal electrodes are typically made of silver or palladium and are attached to leads that protrude from the ceramic disc body.

Ceramic disc capacitors have various capacitance values, typically ranging from a few picofarads (pF) to a few hundred nanofarads (nF). They are also available in multiple voltage ratings, typically ranging from 50 to 500 volts.

One of the main advantages of ceramic disc capacitors is their high reliability, as they are not prone to the same failure modes as electrolytic capacitors. They are also inexpensive compared to other capacitors such as tantalum and aluminium electrolytic.

However, ceramic disc capacitors also have some limitations. They are sensitive to mechanical stress and can crack or fail if subjected to excessive vibration or shock. They also have a nonlinear capacitance behaviour that can limit their use in some applications. Additionally, they are unsuitable for use in high-precision circuits, as their tolerance can vary by as much as 20%.

Ceramic Disc Capacitor Values

Ceramic disc capacitors are a type of ceramic capacitor commonly used in high-frequency circuits and applications where size and cost are essential factors. They are typically available in various capacitance values, voltage ratings, and tolerances.

The capacitance values of ceramic disc capacitors can range from a few picofarads (pF) to a few hundred nanofarads (nF), with the most common values falling between 10 pF and one nF.

Ceramic disc capacitors are often marked with a three-digit code indicating the capacitance value in picofarads. The first two digits represent the significant figures, and the third digit represents the number of zeros to add to the end of the value. For example, a capacitor marked with the code “472” would have a capacitance value of 47 x 10^2 pF, or 4.7 nF.

In addition to capacitance values, ceramic disc capacitors are available in various voltage ratings and tolerances. The voltage rating of a ceramic disc capacitor should be selected based on the maximum voltage that will be applied to the capacitor in the circuit.

The tolerance of a ceramic disc capacitor indicates the maximum deviation from the nominal value and is typically expressed as a percentage. Common tolerances include ±5%, ±10%, and ±20%. Overall, ceramic disc capacitors offer a range of capacitance values, voltage ratings, and tolerances that make them suitable for a wide range of electronic applications.

Applications of Ceramic Capacitors

Ceramic capacitors are widely used in multiple electronic applications due to their small size, high stability, and low cost. Some of the most common applications of ceramic capacitors include the following:

Decoupling and filtering

Ceramic capacitors and filtering circuits are used in the decoupling circuit to remove unwanted electrical noise and ripple from power supplies and signal lines. They are often used in combination with electrolytic capacitors for optimal performance.

Timing and oscillation

Ceramic capacitors are used in timing and oscillation circuits to control the frequency and period of signals. They are commonly used in crystal oscillators and RC timing circuits.

Memory storage

Ceramic capacitors like DRAM and SRAM are used in memory storage circuits to store and release data.

Coupling and blocking

Ceramic capacitors are used in coupling and blocking circuits to transfer signals from one circuit to another while blocking DC signals only the ac signal.

EMI suppression

Ceramic capacitors are used in EMI suppression circuits to reduce electromagnetic interference in electronic systems.

Temperature compensation

Ceramic capacitors are used in temperature compensation circuits to maintain the stability of electronic circuits over a wide range of temperatures.

Disadvantages of Ceramic Capacitors

While ceramic capacitors offer many advantages, they also have some disadvantages that should be considered in specific applications. Some of the disadvantages of ceramic capacitors include the following:

Limited capacitance range

Ceramic capacitors have a limited capacitance range compared to other capacitors, such as electrolytic and film capacitors. The maximum capacitance of a ceramic capacitor is typically in the field of a few microfarads. In contrast, electrolytic capacitors can have capacitance values ranging from a few microfarads to several hundred farads.

Voltage dependence of capacitance

Ceramic capacitors’ capacitance depends on the applied voltage, which can cause the capacitance to vary with the voltage applied to the capacitor. This effect is known as the voltage coefficient, and it can cause changes in the capacitance that may affect the circuit’s performance.

Limited temperature range

While ceramic capacitors have excellent temperature stability, they are typically limited to a narrow temperature range. They may exhibit a significant drop in capacitance at high frequencies and temperatures above or below their rated temperature range.

Piezoelectric effects

Ceramic capacitors can exhibit piezoelectric effects, which can cause mechanical stress to be converted into electrical energy or vice versa. This effect can be problematic in some applications, such as in high-vibration environments.

Class 2 Ceramic Capacitors

Class 2 ceramic capacitors are a type of ceramic capacitor that is known for their high volumetric efficiency and low cost. They are typically made from ceramic dielectric materials, such as barium titanate or lead zirconate (PZT). They are classified based on their temperature coefficient of capacitance (TCC) and voltage rating.

Class 2 ceramic capacitors have a high dielectric constant, which means they can store a large amount of charge in a small volume. This makes them ideal for applications where space is premium, such as portable electronic devices.

Class 2 ceramic capacitors also have a high self-resonant frequency (SRF) and a low equivalent series resistance (ESR), making them well-suited for high-frequency circuits.

One of the main advantages of Class 2 ceramic capacitors is their low cost compared to other capacitors, such as tantalum and aluminium electrolytic capacitors. They are also highly reliable and have excellent temperature stability, making them suitable for various electronic applications.

However, Class 2 ceramic capacitors also have some disadvantages, including a high voltage coefficient of capacitance, which means the capacitance can vary with applied voltage, and an increased ageing rate, which can cause the capacitance to change over time. They also have a nonlinear capacitance behaviour, which can limit their use in some applications.

Frequently asked questions

Can all electrolytic capacitors be replaced with ceramic capacitors?

While ceramic capacitors offer several advantages over electrolytic capacitors, such as small size, high stability, and low cost, replacing all electrolytic capacitors with ceramic capacitors is impossible.

This is because electrolytic capacitors have specific characteristics not easily replicated by ceramic capacitors, particularly regarding capacitance value, voltage rating, and low-frequency behaviour.

Electrolytic capacitors are often used in circuits requiring high capacitance and voltage ratings. Ceramic capacitors are limited in their capacitance range, typically ranging from a few picofarads to a few microfarads. In contrast, electrolytic capacitors can have capacitance values ranging from a few microfarads to several hundred farads.

Additionally, ceramic capacitors may not have the required voltage rating to replace high-voltage electrolytic capacitors used in power supplies and other applications.

How long does a ceramic capacitor last?

The lifespan of a ceramic capacitor depends on several factors, including the quality of the capacitor, the operating conditions, and the application.

Generally speaking, ceramic capacitors are known for their excellent reliability and can last many years when operated within their rated specifications. However, ceramic capacitors can fail over time, like any electronic component, due to voltage stress, temperature, and ageing.

What is the tolerance of ceramic capacitors?

The tolerance of a ceramic capacitor refers to the maximum deviation from the nominal value, typically expressed as a percentage.

Standard tolerances for ceramic capacitors include ±5%, ±10%, and ±20%. The tolerance is an important parameter to consider when selecting capacitors for a specific application, as it determines the maximum allowable deviation from the desired value.

Are ceramic capacitors sensitive to heat?

Ceramic capacitors are relatively insensitive to heat than other capacitors, such as electrolytic capacitors. They are typically rated for a wide temperature range, with operating temperatures ranging from -55°C to +125°C.

However, it is still important to avoid operating ceramic capacitors at temperatures outside their rated range, as excessive heat can cause the capacitance to change and shorten the capacitor’s lifespan. It is also important to note that rapid temperature changes or thermal shock can cause ceramic capacitors to crack or fail, so care should be taken when handling and installing them.

Conclusion

In conclusion, ceramic capacitors are fundamental in various electronic circuits, from consumer electronics to industrial applications. They offer several advantages over other capacitors, including their small size, low cost, and high reliability.

With their wide range of capacitance values, voltage ratings, and sizes, ceramic capacitors are versatile components that can be used in many electronic applications.

Despite their limitations, they remain popular among electronic designers due to their wide availability, affordability, and robustness. Ceramic capacitors are critical in modern electronics and will likely remain essential for many years.