Meta Description

Learn about the importance of film capacitors in electronics, including their various types and how to choose the right one for your application.

Introduction:

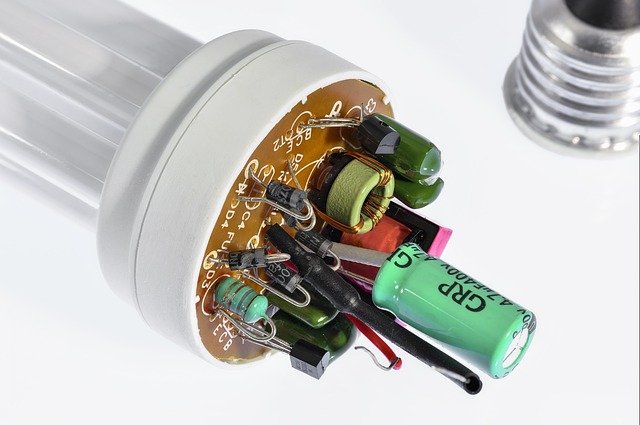

Film capacitors are among electronic circuits’ most commonly used capacitors due to their excellent electrical characteristics and reliability. They are made of thin plastic films coated with metal on both sides and are available in various capacitance values and voltage ratings.

Film capacitors are a type of electronic component used for storing and releasing electrical energy. They are constructed from a thin film of metal, or metal oxide deposited onto a non-conductive material such as polyester, polystyrene, or polypropylene. The resulting structure forms a sandwich-like structure, with the metal film acting as one of the electrodes and the non-conductive material acting as the dielectric.

Film capacitors have various applications in various electronic devices, including power supplies, audio equipment, and lighting systems. This article will explore the importance of film capacitors in electronics, their different types, and how to choose the right one for your application.

Importance of Film Capacitors

When designing a power supply circuit, it is essential to include voltage smoothing capacitors to reduce voltage ripple and decoupling capacitors to prevent noise coupling between different components. Electrolytic capacitors are often used for higher capacitance values, while PP film capacitors and film capacitors are generally preferred for their low dielectric losses and high capacitance stability.

As stated, Film capacitors are popular in electronic circuits due to their high capacitance stability over various temperatures and frequencies. They also have low losses and excellent self-healing properties, meaning they can recover from small punctures or breakdowns in the dielectric material.

The importance of film capacitors in electronic circuits cannot be overstated. They are used in various applications, including power supplies, audio equipment, and electronic filters. They provide high stability, low losses, and excellent self-healing properties, making them a reliable and cost-effective solution for many electronic designs.

Film capacitors play a crucial role in many electronic applications. They often store and release electrical energy, filter unwanted signals, and decouple power supplies.

Applications of Film Capacitors

Below are some specific examples of their importance:

Power supply applications:

In power supply applications, film capacitors are used to smooth out voltage fluctuations and reduce noise on the output. They help provide stable voltage levels to sensitive electronic devices, reducing the risk of damage due to voltage spikes or drops.

Audio applications:

Film capacitors are commonly used in audio circuits to filter out unwanted signals and reduce noise. They help improve the sound quality of audio equipment by reducing distortion and improving clarity.

Motor applications:

Film circuits often use film capacitors to provide start and run power capacitors themselves. They help control the starting and running currents of the motor, improving efficiency and reducing wear and tear.

Lighting applications:

Film capacitors are also used in lighting circuits to improve power factors and reduce harmonic distortion. They help improve the efficiency of lighting systems and reduce energy consumption.

Overall, film capacitors are an essential component in many electronic applications. They provide high reliability, low losses, and excellent self-healing properties, making them a cost-effective solution for various electronic designs.

Polyester Film Capacitors

Polyester film capacitors are a type of film capacitor that uses a thin layer of metalized polyester film as the dielectric material. They are often referred to as Mylar capacitors, which is a trademarked name for a type of polyester power film capacitors.

Polyester film capacitors are popular in electronic circuits due to their low cost, high capacitance stability, and small size. They are commonly used in power supply applications, audio equipment, and electronic filters. They are also used in lighting circuits, motor circuits, and other applications where high reliability and low cost are essential.

Polyester on film capacitors are widely available in various capacitance values, voltage ratings, and tolerances. They typically have a capacitance range of 1nF to 10µF, with voltage ratings ranging from 50V to 630V. Tolerance values usually range from 5% to 20%.

Polyester film capacitors offer several advantages over other types of capacitors. Low losses mean they don’t dissipate as much energy as other capacitors. They are also highly stable over various temperatures and frequencies, making them suitable for high-performance circuits. They also have excellent self-healing properties, allowing them to recover from small punctures or breakdowns in the dielectric material.

One disadvantage of polyester film capacitors is that they are unsuitable for high-temperature applications. They have a maximum temperature rating of around 100°C, which limits their use in high-temperature environments. In addition, they are not as reliable as other types of capacitors, such as ceramic or even tantalum capacitors.

Polypropylene Film Capacitor

Polypropylene film capacitors are a type of film capacitor that uses a thin layer of metalized polypropylene film as the dielectric material. They are known for their excellent stability over various temperatures and frequencies, low losses, and high insulation resistance.

Polypropylene film capacitors are commonly used in applications where high reliability and stability are critical, such as in power supply circuits, audio equipment, and electronic filters. They are also used in motor circuits, lighting circuits, and other applications where high insulation resistance is essential.

Polypropylene film capacitors are available in various capacitance values, voltage ratings, and tolerances. They typically have a capacitance range of 100pF to 10µF, with voltage ratings ranging from 50V to 1600V. Tolerance values usually range from 1% to 10%.

One of the main advantages of polypropylene film capacitors is their excellent stability over a wide range of temperatures and frequencies. They are highly resistant to temperature changes, making them ideal for high-temperature environments. They also have shallow losses, meaning they don’t dissipate as much energy as other capacitors.

Another advantage of polypropylene film capacitors is their high insulation resistance. They can maintain their capacitance values even at high temperatures and frequencies, essential for ensuring accurate and reliable performance in electronic circuits.

One disadvantage of polypropylene film capacitors is their relatively high cost compared to other capacitors, such as polyester film capacitors. They are also physically more prominent than other capacitors, which can disadvantage space-constrained applications.

Metallized Film Capacitors

Metalized film capacitors, also known as self-healing film capacitors, are a type of film capacitor that uses a thin layer of metalized film as the dielectric material. They are designed to be self-healing, meaning that if the dielectric material breaks down due to a voltage surge or other electrical stress, the metalized capacitor can repair itself and continue to function.

Metalized film capacitors are commonly used in high-voltage and high-frequency applications, such as power supplies, audio equipment, and electronic filters. They are also used in motor circuits, lighting circuits, and other applications where high reliability and stability are critical.

Metalized film capacitors are available in various capacitance values, voltage ratings, and tolerances. They typically have a capacitance range of 100pF to 10µF, with voltage ratings ranging from 50V to 1600V. Tolerance values usually range from 1% to 10%.

One of the main advantages of metalized film capacitors is their self-healing properties. Suppose the dielectric material breaks down due to a voltage surge or other electrical stress. In that case, the metalized film capacitor can repair itself by forming a new dielectric layer over the damaged area. This helps ensure reliable and long-lasting performance in high-stress applications.

Another advantage of metalized film capacitors is their low losses, which means they don’t dissipate as much energy as other capacitors. This can help improve the efficiency of electronic circuits and reduce power consumption.

One disadvantage of metalized film capacitors is that they can be more expensive than other types, such as polyester capacitors or polypropylene film capacitors. They are also physically more significant than other plastic film capacitors, which can disadvantage space-constrained applications.

Comparing Voltage Ratings for Different Types of Film Capacitors

Different film capacitors have different voltage ratings determining the maximum voltage they can safely handle. Here’s a comparison of the voltage ratings for some commonly used film capacitors:

Polyester film capacitors

These capacitors typically have voltage ratings between 50V and 630V. They are commonly used in low-voltage applications such as audio equipment, lighting, and power supply circuits.

Polypropylene film capacitors

These capacitors typically have voltage ratings between 50V and 1600V. They are commonly used in high-voltage applications such as power supplies, motor circuits, and electronic filters.

Metalized film capacitors

These capacitors typically have voltage ratings between 50V and 1600V. They are commonly used in high-frequency and high-voltage applications requiring self-healing properties.

Polycarbonate film capacitors

These capacitors typically have voltage ratings between 63V and 400V. They are commonly used in low-voltage applications such as audio equipment and power supply circuits.

Polystyrene film capacitors

These capacitors typically have voltage ratings between 50V and 630V. They are commonly used in low-voltage applications such as audio equipment, filters, and oscillators.

Selecting a film capacitor with the appropriate voltage rating for your application is essential to ensure reliable and safe operation. Selecting a capacitor with a voltage rating that is too low can result in premature failure or even safety hazards. Choosing a capacitor with a voltage rating that is too high can result in unnecessary costs and a larger physical size.

Tips for Choosing the Right Film Capacitor for Your Application

Choosing a suitable film capacitor for your application can ensure your electronic circuit’s reliable and stable operation. Here are some tips for selecting a suitable film capacitor:

Determine the required capacitance value.

The first step in selecting a film capacitor is determining the required capacitance value for your application. This value is typically specified in the circuit design or can be calculated based on the operating frequency and required filtering or coupling properties of power film.

Consider the voltage rating.

The capacitor’s voltage rating is also an essential factor to consider. Select a capacitor with a voltage rating sufficient for your application to prevent premature failure or safety hazards.

Choose the appropriate dielectric material.

Different film capacitors use different dielectric materials, each with unique properties. For example, polyester film capacitors are affordable and offer good electrical properties, while polypropylene film ceramic capacitors tend to provide better stability and temperature performance. Choose the dielectric material that is best suited for your specific application.

Consider the temperature and frequency range.

Film capacitors have different performance characteristics at different temperatures and frequencies. Select a first film capacitor rated for your application’s temperature and frequency range.

Look at tolerance and stability.

Film capacitors have a tolerance rating determining how closely the actual capacitance value matches the rated value. Choose a capacitor with a tolerance that is appropriate for your application. Additionally, some film capacitors offer better stability over time and temperature than others, which can be crucial in critical applications.

Consider the physical size and mounting options.

Film capacitors are available in a range of sizes and mounting options. Select a capacitor that fits your application and can easily mount thin plastic film.

Overall, selecting the suitable thin film capacitor for your application requires careful consideration of various factors, including capacitance value, voltage rating, dielectric material, temperature and frequency range, tolerance and stability, and physical size and mounting options.

Ceramic vs. Film Capacitors?

Ceramic and film capacitors are two types of capacitors used in electronic circuits. Ceramic capacitors are typically made of ceramic materials with metal electrodes on either side, while film capacitors are made of thin plastic films coated with metal on both sides.

Ceramic capacitors are smaller and have a lower cost per unit capacitance but have a smaller capacitance range and poorer frequency stability than film capacitors. On the other hand, film capacitors are larger and more expensive but offer a more comprehensive range of capacitance values and better frequency stability.

Overall, the choice between ceramic and film capacitors depends on the electronic circuit’s specific requirements and the capacitor’s performance characteristics needed to meet those requirements.

Can I Use Ceramic Instead of Film Capacitor?

In general, it may be possible to use a ceramic capacitor instead of a film capacitor, but it depends on the specific requirements of your electronic circuit.

Ceramic capacitors have different electrical characteristics and performance compared to film capacitors, so using a ceramic capacitor instead of a film capacitor could impact the overall functionality of the circuit. If the circuit requires a capacitor with high-frequency stability, low losses, or a high voltage rating, then using a ceramic capacitor may not be suitable.

However, a ceramic film foil capacitor may be viable if the circuit requires a more minor or lower-cost capacitor. Therefore, it’s essential to carefully evaluate the requirements of your circuit before deciding whether a ceramic capacitor can be used instead of a film capacitor.

Conclusion

In conclusion, film capacitors are essential in electronic circuits due to their excellent electrical characteristics, reliability, and versatility. They are available in various types, including polyester, polypropylene, and metalized film capacitors, each with advantages and limitations.

Choosing the correct type of film capacitor for your application is crucial to ensuring your electronic circuit’s proper function and longevity. Factors such as capacitance value, voltage rating, frequency stability, and temperature range should be carefully considered when selecting a film capacitor.

By understanding the importance of film capacitors in electronics and selecting the appropriate type of capacitors, you can ensure that your electronic devices operate efficiently and reliably.