Meta Description:

Discover the construction, properties, characteristics, and applications of film capacitors. Learn how to choose the right type for your electronic circuits.

Introduction:

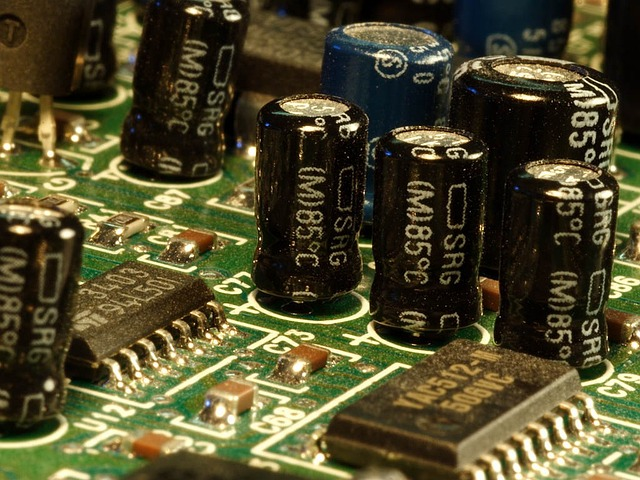

Capacitors are essential components used in electronic circuits to store electrical charge and energy. Film capacitors, in particular, are a type of capacitor that utilizes a thin plastic film as a dielectric material. They offer several advantages over other capacitors, including high reliability, stability, and low cost.

The film is coated with a thin layer of metal, typically aluminum or zinc, to form the electrodes. Film capacitors offer several advantages, including high reliability, stability, and low cost. They are widely used in electronic circuits, particularly high-frequency and high-voltage applications.

Now that we have introduced the topic of film capacitors and their advantages let us explore their construction, properties, and applications in more detail. Understanding these key aspects will help you select the suitable film capacitor for your circuit design and application.

Breakdown of Film Capacitors

Film capacitors are a type of electronic component used in multiple applications, from power supplies and audio equipment to lighting and motor circuits. They are constructed using a thin layer of insulating plastic film, which acts as the dielectric, and a thin layer of metal foil, usually aluminum, which acts as the electrodes.

Film capacitors come in various types, including plastic film capacitors, metalized film capacitors, and power film capacitors, each with different construction and properties. Plastic films, such as polypropylene film and pp film capacitors, are commonly used in film capacitors as dielectric materials for their stable characteristics.

Film foil capacitors, including voltage smoothing capacitors and decoupling capacitors, offer high performance in power and signal applications. In contrast, electrolytic capacitors provide high capacitance but lower voltage ratings than film capacitors.

In summary, ceramic and film capacitors, including plastic film, ceramic capacitors, and metalized film capacitors, provide a range of options for designers, depending on their specific application requirements.

One of the primary advantages of film capacitors is their high capacitance-to-volume ratio. This means they can store much electrical charge in a relatively small space. They are also known for their high reliability, long service life, and low cost.

Common Types of Film capacitors

There are several different film capacitors, each with unique properties and applications. Some of the most common types of film capacitors include:

Polyester film capacitors: These are the most common type of film capacitor widely used in electronic circuits. They have a high dielectric constant and are available in various capacitance values and voltage ratings.

Polypropylene film capacitors: These are similar to polyester film capacitors but have a higher breakdown voltage and lower dissipation factor. They are often used in high-frequency applications.

Polycarbonate film capacitors: These paper capacitors are used in applications that require high stability and low losses.

Metalized polypropylene film capacitors: These are similar to polypropylene film capacitors but have a thin metal coating on the electrodes. This improves their performance at high frequencies.

Metalized polyester film capacitors: These are similar to metalized polypropylene film capacitors but use polyester film as the dielectric.

Construction of Film Capacitors

Film capacitors are constructed using a thin layer of insulating plastic film and a thin layer of metal. The plastic film acts as the dielectric, while the metal layer act as the electrode.

The construction process typically involves the following steps:

Film preparation

The plastic film is first prepared by extruding a thin sheet of plastic, usually polyester or polypropylene, to a specified thickness. The thickness of the film determines the capacitance value of the capacitor.

Metallization

The plastic film is then coated with a thin layer of metal, usually aluminum, on one or both sides. The metal layer serves as the electrode and is responsible for conducting electricity.

Winding

The metal-coated plastic film is then wound into a cylindrical shape to create a compact capacitor. The distance between the electrodes determines the voltage rating of the capacitor.

Encapsulation

The wound capacitor is then encapsulated in a protective material, such as epoxy resin or plastic, to protect it from external environmental factors and to provide mechanical stability.

After construction, the film capacitor is tested to ensure it meets the desired capacitance value and voltage rating. The testing process involves measuring the capacitance and dissipation factors, which measure the film foil capacitor’s energy loss.

In conclusion, film capacitors are constructed using a simple and reliable process that involves coating a thin layer of plastic film with a thin layer of metal, winding it into a cylindrical shape, and encapsulating it in a protective material. This construction process allows for a high capacitance-to-volume ratio, making film capacitors suitable for various electronic applications.

Properties of Film Capacitors

Film capacitors possess several properties that make them useful for various electronic applications. Some of these properties include:

High reliability

Film capacitors are known for their high reliability and long service life. They can operate at high temperatures and are not affected by moisture or other environmental factors, making them ideal for use in harsh operating conditions.

Low dissipation factor

The dissipation factor of a capacitor is a measure of its energy loss. Film capacitors have a low dissipation factor, which means they are efficient at storing and releasing electrical energy.

High insulation resistance

The insulation resistance of a capacitor is a measure of its ability to resist leakage current. Film capacitors have a high insulation resistance, meaning they can hold a charge for a long time without losing it.

High capacitance-to-volume ratio

Film capacitors have a high capacitance-to-volume ratio, meaning they can store a large amount of electrical charge in a relatively small space.

Low-cost

Film capacitors are generally less expensive than other capacitors, making them a popular choice for a wide range of electronic applications.

Capacitance values and voltage ratings

Film capacitors are available in various capacitance values and voltage ratings, making them suitable for various electronic applications.

Good frequency response

Film capacitors have a good frequency response, meaning they can work effectively at high frequencies.

Characteristics of a Film Capacitor

Film capacitors have several essential characteristics that make them useful for electronic circuits. These include:

Capacitance

The capacitance of a capacitor is its ability to store an electrical charge. Film capacitors are available in various capacitance values, typically ranging from a few picofarads to several microfarads. The capacitance of a film capacitor is determined by the thickness and area of the plastic film, as well as the distance between the metal electrodes.

Voltage rating

It is the maximum voltage it can safely withstand. Film capacitors have a high voltage rating, typically ranging from a few to several thousand volts. The voltage rating of a film capacitor is determined by the thickness and distance between the film caps and the electrodes, as well as the dielectric strength of the plastic film.

Temperature coefficient:

A capacitor’s temperature coefficient measures how its capacitance changes with temperature. Film capacitors typically have a low temperature coefficient, meaning their capacitance remains relatively stable over a wide range of temperatures.

Frequency response:

The frequency response of a capacitor is its ability to work effectively at high frequencies. Film capacitors have a good frequency response, making them suitable for high-frequency applications.

Dissipation factor:

The dissipation factor of a capacitor is a measure of its energy loss. Film capacitors have a low dissipation factor, which means they are efficient at storing and releasing electrical energy.

Tolerance:

A capacitor’s tolerance measures how closely its actual capacitance value matches its nominal value. Film capacitors typically have a low tolerance, meaning their real capacitance value is close to their little value.

Working Principle of a Film Capacitor

The working principle is based on the electrical properties of the dielectric material, which is the insulating plastic film that separates the metal electrodes. An electric field is created between the two electrodes when a voltage is applied across the capacitor. The dielectric material stores energy in the form of an electric charge.

The energy inside the capacitor is directly proportional to the capacitance and the square of the voltage across it. The energy inside the capacitor can be released when the voltage across the capacitor is reduced or connected to a load.

The plastic film in film capacitors is a good insulator, meaning it does not conduct electricity. This ensures that the electric charge stored in the plastic film capacitor remains isolated from the surrounding circuitry. The plastic film is also stable over various temperatures and frequencies, making film capacitors suitable for high-performance electronic circuits.

Applications of a Film Capacitor

Due to their favorable properties and characteristics, film capacitors are widely used in various electronic circuits and applications. Some of the standard applications of film capacitors are:

AC and DC filtering: Film capacitors are used in power supply circuits to filter out unwanted AC or DC signals and provide smooth and stable power to electronic devices.

Coupling and decoupling circuits: Film capacitors are used to couple or decouple signals between stages of an electronic circuit. They help to isolate one stage from another and reduce interference and noise.

Timing circuits: Film capacitors are used in timing circuits to control the frequency and duration of electronic signals.

Motor start and run capacitors: Film capacitors are used in motor circuits to start and run motors by providing a phase shift in the AC voltage.

Audio applications: Film capacitors are used in audio circuits for coupling, decoupling, and filtering to provide high-quality audio signals.

Lighting applications: Film capacitors are used in lighting circuits for power factor correction, which improves the efficiency of the circuit and reduces energy consumption.

High-frequency applications: Film capacitors are used in high-frequency circuits such as radio frequency (RF) circuits and telecommunications equipment due to their excellent frequency response and low dissipation factor.

Voltage regulation: Film capacitors are used in voltage regulator circuits to smooth out voltage fluctuations and provide stable DC voltage output.

Self-healing Property of Metalized film capacitors

Metalized film capacitors can self-heal, a unique characteristic that sets them apart. The self-healing feature results from using a metalized layer on the dielectric and metalized film capacitor.

The metalized layer can break down due to a high voltage or current surge. This breakdown creates a small electrical arc between the two metalized layers, which vaporizes a small amount of the dielectric material, creating a conductive path between the two layers.

Once the voltage or current surge subsides, the electrical arc extinguishes, removing the conductive path. The vaporized dielectric material re-condenses and the metalized layer is “healed,” restoring the capacitor’s original capacitance value.

The self-healing capability of metalized film capacitors allows them to maintain their reliability and performance over time, even when subjected to high frequency and voltage responses and current surges. This feature makes them popular in high-power and high-voltage applications, such as inverter circuits, power supplies, and motor control circuits.

Internal Structure of Film Capacitor to increase voltage rating

The internal structure of a film capacitor can be designed to increase its voltage rating. The voltage rating of a capacitor refers to the maximum voltage that the capacitor can withstand without breaking down or failing.

One way to increase the voltage rating of a film capacitor is to use multiple dielectric film layers. The dielectric film separates the two electrodes in the capacitor, and adding more film layers increases the distance between the metallic layers and the electrodes, which can increase the capacitor’s voltage rating. Each film layer is metalized with a thin metal layer to form the electrodes.

Another way to increase the voltage rating of a film capacitor is to use a series connection of multiple capacitors. In this arrangement, several identical capacitors are connected in series, and the total voltage rating of the series connection is equal to the sum of the individual voltage ratings of the capacitors.

This approach is commonly used in high-voltage applications where a single capacitor cannot meet the required voltage rating.

In addition, the thickness of the dielectric material can also affect the capacitor’s voltage rating. Thicker dielectric materials can provide a higher breakdown voltage, increasing the capacitor’s voltage rating.

Electrical characteristics of a Film Capacitor

Film capacitors have several important electrical characteristics for their performance and application. Here are some of the vital electrical features of a film capacitor:

Capacitance:

The capacitance of a film capacitor is its ability to store electric charge, measured in Farads (F). The capacitance value is determined by the area of the capacitor’s electrodes, the distance between the electrodes, and the dielectric constant of the dielectric material.

Voltage rating:

The voltage rating of a film capacitor is the maximum voltage it can withstand without breaking down or failing. This rating is determined by the thickness and type of dielectric material used and the distance between the electrodes.

Dissipation factor:

The dissipation factor of a film capacitor is a measure of the energy lost as heat when the capacitor is charged and discharged. It is expressed as a ratio of the capacitor’s equivalent series resistance (ESR) to its capacitive reactance (Xc) at a specific frequency. A lower dissipation factor indicates a more efficient capacitor.

Insulation resistance:

It is the resistance between its electrodes, measured in Ohms. A high insulation resistance indicates that the capacitor has good insulation properties and can maintain its capacitance value over time.

Frequency response:

The frequency response of a film capacitor is its ability to respond to signals of different frequencies. Film capacitors have a low-frequency dependence, making them suitable for high-frequency applications.

Temperature coefficient:

The temperature coefficient of a film capacitor is the change in capacitance value with temperature changes. Film capacitors typically have a low-temperature coefficient, meaning their capacitance value remains stable over a wide temperature range.

Conclusion

In conclusion, film capacitors are versatile and reliable components widely used in electronic circuits for their stable performance and cost-effectiveness. Film capacitors offer several advantages, from construction to electrical characteristics and applications.

As electronic devices become more complex and demanding, film capacitors will continue to play a crucial role in ensuring smooth and efficient operation.