Meta Description:

Discover the most common type of capacitor used in electronic circuits. Learn about its characteristics, applications, and advantages.

Introduction:

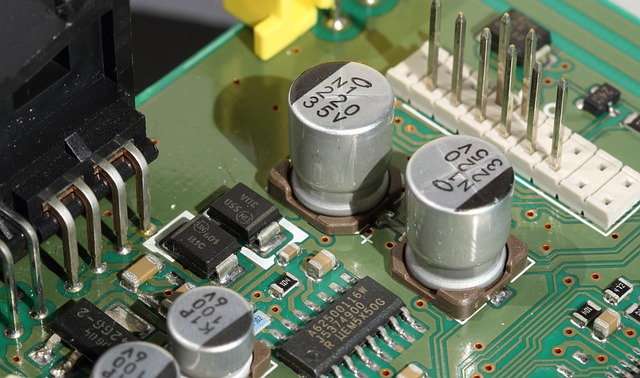

Capacitors are fundamental electronic circuit component that stores and releases electrical energy. They come in various types and configurations, each with unique characteristics and applications.

Capacitors are classified based on their dielectric material, which determines their characteristics, such as capacitance, voltage rating, temperature range, size, and form factor. The most common types are ceramic, electrolytic, film, tantalum and silver mica capacitors. However, among these, electrolytic capacitors carry the most prominence.

As electronic circuits become more complex and miniaturized, selecting the right type of capacitor is critical to ensure the correct function of the circuit. This article will overview the most common capacitors used in electronic circuits, their characteristics, and their applications.

Introducing Capacitors – What they are and What they do?

Capacitors are passive electronic components that store and release electrical energy. They are commonly used in electronic circuits to perform various functions, such as filtering, timing, and smoothing.

A capacitor comprises two conductive plates separated by an insulating material called a dielectric. The capacitance of a capacitor is determined by the surface area of the plates, the distance between them, and the type of ceramic dielectric being used.

When a voltage is applied across the plates of a capacitor, it causes electrons to accumulate on one plate and move away from the other plate, creating an electric field. The capacitor stores that energy in the form of an electric field.

When the power supplies the voltage source is removed, the stored electrical energy in the supercapacitor is released, and the capacitor discharges. Depending on the circuit’s capacitance and load, this discharge can be instantaneous or occur over a while.

Capacitors are used in a variety of electronic circuits to perform specific functions. For example, capacitors filter out high-frequency noise in power supply circuits and provide a stable voltage output. In timing circuits, capacitors control the rate at which a circuit switches on and off. In audio circuits, capacitors filter out low-frequency noise and prevent a DC voltage from passing through a speaker.

Capacitors come in various shapes and sizes, from tiny surface-mount capacitors used in mobile devices to large capacitors used in power grids. They are also available in different types, such as ceramic, electrolytic, tantalum, film, and mica capacitors, each with unique characteristics and applications.

Ceramic Capacitors

Ceramic capacitors are made of ceramic material with a conductive metal layer on both sides of the ceramic disk. They are widely used in electronic circuits due to their low cost, small size, and high capacitance values. Ceramic capacitors are available in two main types: class 1 and class 2.

Class 1 ceramic capacitors have very high stability and low losses, making them suitable for applications requiring high accuracy and stability, such as timing and oscillator circuits.

Class 2 ceramic capacitors have a higher capacitance per unit volume than class 1 ceramic capacitors but with lower strength and higher losses. They are suitable for applications with higher capacitance values, such as power supply decoupling and noise filtering.

Ceramic capacitors have several advantages over other types of capacitors. They have a high voltage rating, typically ranging from a few to several hundred volts, and can withstand high temperatures, making them suitable for use in harsh environments. They also have a wide range of capacitance values, ranging from a few picofarads (pF) to several microfarads (μF), making them versatile components in various circuits.

However, ceramic capacitors also have some disadvantages. They exhibit a piezoelectric effect, leading to voltage spikes and circuit noise. They can also have a high-temperature coefficient, which means their capacitance can vary with temperature, making them unsuitable for circuits requiring high accuracy and stability over a wide temperature range.

Tantalum Capacitors

Tantalum capacitors are electrolytic capacitors that use tantalum metal as the anode. They are widely used in electronic circuits where a high capacitance value and high reliability are required.

Tantalum capacitors are constructed with a tantalum metal anode covered with a thin layer of tantalum pentoxide as the dielectric material. The cathode is made of a conductive material, and the whole tantalum capacitor part is sealed in an epoxy or plastic casing.

Tantalum capacitors are polarized, meaning they have a positive and negative lead and must be installed with the correct polarity to function correctly. Tantalum capacitors have several advantages over other types of capacitors. They have a high volumetric efficiency, which means they can achieve a very high capacitance value in a small size.

They also have a low leakage current, which results in low power dissipation and high reliability. Tantalum capacitors have a high operating temperature range, typically between -55°C and 125°C, making them suitable for harsh environments.

One of the disadvantages of tantalum capacitors is their higher cost than other types of capacitors. They are also less tolerant of overvoltage conditions, which can result in catastrophic failure if not adequately designed for the circuit. Tantalum capacitors can also be sensitive to thermal and mechanical stress, which can cause cracking of the tantalum oxide layer and lead to failure.

Tantalum capacitors are widely used in electronic circuits, particularly power supply systems and audio circuits. They are also used in high-reliability applications, such as medical equipment and aerospace applications.

Film Capacitors

Film capacitors are a type of capacitor that uses a thin film of metal or metalized plastic as the dielectric material. They are widely used in electronic circuits where high stability, reliability, and low losses are required.

Film capacitors are constructed with a metal or plastic film as the dielectric material, coated with a thin layer of metal electrodes on both sides. Depending on the application, the electrodes can be made of aluminium, zinc, or other metals. The electrodes are typically made with a metal foil that has been metalized or deposited with a thin layer of metal using a process such as sputtering. The metal electrodes are usually connected to leads that extend out of the film capacitor or casing.

There are several film capacitors, including polyester film capacitors, polypropylene, and metalized plastic film capacitors. Polyester film capacitors are low-cost capacitors commonly used in consumer electronics applications.

Polypropylene film capacitors, such as audio circuits, are used in applications with high stability and low losses. Metalized film capacitor capacitors are used in applications where high capacitance values are required in a small size, such as in power supply circuits.

One of the advantages of film capacitors is their high level of stability and low losses. They have a low dissipation factor, meaning that they lose little energy as heat. Film capacitors also have a low-temperature coefficient of capacitance, meaning their capacitance value remains relatively stable over a wide temperature range. Film capacitors are also highly reliable and have a long lifespan.

One of the disadvantages of film capacitors is their relatively low capacitance values compared to electrolytic capacitors. They are also more significant for a given capacitance value, which can disadvantage applications with limited space.

Variable Capacitors

Variable or tuning capacitors have a variable capacitance value that can be adjusted manually or electronically. They are widely used in electronic circuits requiring variable capacitance for tuning or frequency control.

Variable capacitors are constructed with two metal plates separated by a dielectric material, usually air or plastic. One of the plates is fixed, while the other is mounted on a shaft that can rotate, allowing the distance between the plates to be changed, thus, the capacitance value to be adjusted. Variable capacitors can have a capacitance range of a few picofarads up to several hundred, depending on the size of the variable capacitor used.

Variable capacitors can be manually adjusted by turning a shaft or electronically using a voltage to control the distance between the plates. Electronic variable capacitors, such as radio receivers, transmitters, and filters, are commonly used in radio frequency (RF) applications where tuning is required.

One of the advantages of variable capacitors is their variable capacitance range, which allows them to be used in a wide range of applications. They are also relatively easy to use and can be adjusted without requiring special tools or equipment. Variable capacitors are also compact and can be made in a small size, making them suitable for use in portable electronic devices.

One of the disadvantages of variable capacitors is their limited lifespan. The mechanical components of the variable capacitor can wear over time with repeated adjustments, and the contacts can become dirty or corroded, leading to increased resistance and reduced performance. Variable capacitors are also less stable than fixed capacitors, which can result in drift in the capacitance value over time.

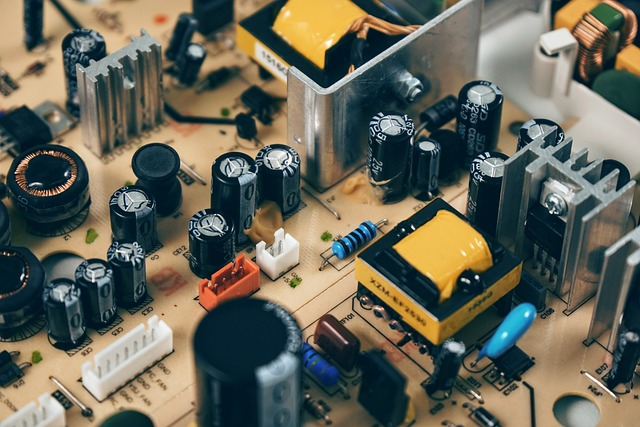

The most popular type of Capacitor – Electrolytic Capacitors

Electrolytic capacitors are a type of capacitor that uses an electrolyte solution as the dielectric material. They are widely used in electronic circuits where high capacitance values are required in a small size, such as in power supply circuits.

Electrolytic capacitors are constructed with two metal plates separated by an electrolyte solution. The plates are usually made of aluminium or tantalum, and the electrolyte solution is typically a liquid or gel that contains ions that conduct electricity. The electrolyte solution forms a thin layer of oxide on the surface of the metal plates, which acts as the dielectric material.

Electrolytic capacitors can have a capacitance value ranging from a few microfarads up to several thousand microfarads, depending on the size and type of capacitor. They are available in two main capacitor types: aluminum electrolytic capacitors and tantalum electrolytic capacitors.

Aluminium electrolytic capacitors are the most commonly used type of aluminium electrolytic capacitor. They are low-cost and have a high capacitance value in a small size. However, they are less stable than other capacitor types made of aluminium electrolytic capacitors and can have a high leakage current, which can cause reliability issues in some applications.

Tantalum electrolytic capacitors are another type of electrolytic capacitor technology that offers higher stability and lower leakage current than aluminium electrolytic capacitors. They are also more expensive and have a lower capacitance value in a small size.

One of the advantages of electrolytic capacitors is their high capacitance value in a small size, which makes them ideal for use in power supply circuits and other applications where space is limited. They are also relatively low-cost compared to other capacitors, making them popular in many electronic designs.

One of the disadvantages of electrolytic capacitors is their relatively low reliability compared to other types of capacitors. They can have a limited lifespan, primarily if operated at high temperatures or with high ripple currents. They can also have a high equivalent series resistance (ESR) and equivalent series inductance (ESL), affecting their performance in some applications.

Characteristics of Electrolytic Capacitors

Electrolytic capacitors are polarized capacitors that are commonly used in electronic circuits. They have several key characteristics, including high capacitance values, low cost, and compact size.

Additionally, electrolytic capacitors can handle high voltages and have low leakage currents. However, they are sensitive to temperature and can lose large capacitance values over time.

They also have a limited lifespan and can fail if subjected to excessive voltage or heat. Overall, electrolytic capacitors are an excellent choice for applications requiring high capacitance values in small sizes and low cost. However, they should be selected carefully based on the application’s requirements to ensure reliable operation.

Applications for electrolytic capacitors

Electrolytic capacitors are widely used in electronic circuits where high capacitance values are required in a small size, particularly in power supply circuits. Some typical applications for electrolytic capacitors include:

Power supply circuits

Electrolytic capacitors are used in power supply circuits to smooth out the output voltage and reduce ripple. They are often connected in parallel with a smaller, high-quality capacitor, such as a ceramic capacitor, which helps to reduce the ESR and ESL of the electrolytic capacitor.

Audio circuits

Electrolytic capacitors are used as coupling capacitors to block DC voltage and allow the same AC voltage or audio signal to pass through. They are often used with other capacitors, such as film or ceramic, to achieve a desired frequency response.

Motor control circuits

Electrolytic capacitors are used in motor control circuits to reduce electrical noise and provide a stable voltage. They are often used with other capacitors, such as ceramic and film capacitors, to achieve the desired filtering and noise reduction.

Lighting circuits

Electrolytic capacitors, particularly fluorescent and LED lighting, are used in lighting circuits to provide a stable voltage and reduce flicker. They are often used with other capacitors, such as film capacitors, to achieve the desired filtering and noise reduction.

Automotive circuits

Electrolytic capacitors, particularly engine management systems, are used in automotive circuits to provide a stable voltage and reduce electrical noise. They are often used with other capacitors, such as ceramic and film capacitors, to achieve the desired filtering and noise reduction.

How to choose the right type of capacitor for your project or device

Selecting the correct type of capacitor for your project or device is essential to ensure it functions correctly and meets the required specifications. Here are some factors to consider:

Capacitance value

The capacitance value is essential when choosing a capacitor. Determine the required capacitance value based on the application requirements and the operating conditions of the circuit.

Voltage rating

Choose a capacitor with a voltage rating higher than the maximum applied voltage amount the circuit will experience.

Temperature range

Consider the operating temperature range of the power capacitor of the circuit and choose a capacitor that can operate within that range.

Size and form factor

Choose a capacitor with a size and form factor that can fit within the available space in your circuit or device.

Type of capacitor

Consider the advantages and disadvantages of different capacitor types, such as ceramic capacitors, electrolytic capacitors, film capacitors, etc. Choose a ceramic capacitor or type that is suitable for your application.

ESR and ESL

Consider the capacitor’s equivalent series resistance (ESR) and equivalent series inductance (ESL), particularly for applications that require low noise or high stability.

Quality and reliability

Choose a capacitor from a reputable manufacturer and ensure it meets your application’s required quality and reliability standards.

Careful consideration of these factors will help you select a capacitor that meets your requirements and functions correctly in your circuit or device.

Conclusion

In conclusion, capacitors are essential components in electronic circuits that store and release electrical energy. Many different types of capacitors are available, each with unique characteristics and applications. This article has explored the most common types of capacitors, including ceramic, electrolytic, film, and tantalum capacitors.

Whether it’s for filtering noise, smoothing power, or coupling signals, the right type of capacitor is critical for ensuring the correct function of electronic circuits. With the information provided in this article, readers can confidently choose the right kind of capacitor for their project or device.