Meta Description:

Learn how to identify and understand the uses of 4 resistors: carbon film, metal film, wire wound, and metal oxide film. Understand the difference, uses, and how to select the best one for your application.

Introduction:

Resistors are one of the most basic and essential components in electronic circuits. They control the flow of electricity in a circuit and are found in various applications. Understanding the different types of resistors and their uses is essential for anyone working with electronics.

Are you curious about the different resistor types and how to select the right one for your circuit? Understanding the characteristics and uses of each type of resistor can help ensure that your circuit performs as intended.

This article will briefly introduce the four main types of resistors: carbon film, metal film, wire wound, and metal oxide film. We will also discuss each type’s unique characteristics and uses and tips for identifying and selecting the best resistor for a specific application.

Carbon Film Resistors

Carbon film resistors are the most common resistors made by coating a ceramic rod with carbon. They are inexpensive and have a wide range of resistance values, making them a popular choice for many applications.

They are also relatively stable and have a low-temperature coefficient of resistance, which means their resistance does not change much with temperature.

Carbon film resistors are an excellent choice for general use due to their low cost and wide range of resistance values. They are also relatively stable and have a low-temperature coefficient of resistance.

They are commonly used in applications such as audio equipment, power supplies, and digital circuits. They can also be used as voltage dividers, current limiters, and RC filters. Additionally, carbon film resistors are used in automotive and industrial applications where they are exposed to high temperatures and vibration.

To determine if a carbon film resistor is the best choice for a specific application, consider the required resistance value, power rating, and stability requirements.

Metal Film Resistors

Metal film resistors are similar to carbon film resistors but are made by coating a ceramic rod with metal. They are more stable than carbon film resistors and have a lower temperature coefficient of resistance. They also have a lower noise level and are more precise than carbon film resistors.

They are also more precise than thin film resistors and have a lower noise level. They are commonly used in precision applications such as measurement equipment and signal processing circuits. They are also used in audio equipment and power supplies.

In addition, metal film resistors are often used in applications where stability and precision are essential, such as in medical equipment or high-frequency circuits.

When determining if a metal film resistor is the best choice for a specific application, consider the required resistance value, power rating, stability, and precision requirements.

Wire-Wound Resistors

Wire-wound resistors are a type of resistor that uses a wire, typically made of a high-resistance material such as nickel-chromium alloy, wrapped around a ceramic or non-conductive core. Wire-wound linear resistors are made by winding wire around a ceramic or metal core.

They are more stable than carbon film and metal thick film resistors and have a lower temperature coefficient of resistance. They are also more durable and can handle higher power levels.

They are known for their high power handling capabilities and stability over various temperatures and frequencies. They can also be made to exact resistance values, making them useful in precision measurement and control circuits.

Metal Oxide Film Resistors

Metal oxide film resistors are variable resistor that uses a thin layer of metal oxide deposited on a ceramic substrate to create a resistive element. Metal oxide film resistors are made by coating a ceramic rod with metal oxide. They are similar to carbon composition resistors but are more stable and have a lower temperature coefficient of resistance. They are also more precise than carbon film resistors.

The most common metal oxides used are tantalum oxide, titanium oxide, and nickel oxide. These variable resistors are known for their high stability, low noise, and good temperature coefficient of resistance.

Metal oxide film resistors can also be made to exact resistance values, and they can handle high power in compact sizes. They are also relatively lower priced compared to other types of precision resistors.

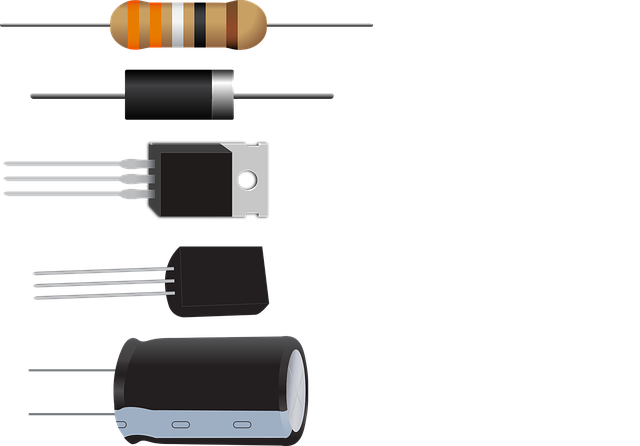

Identification of each Resistor

Identifying the type of resistor can be important when working with electronic circuits, as different types have different characteristics and uses. Here are some tips on how to identify the four main types of resistors:

Identifying Carbon Film Resistors

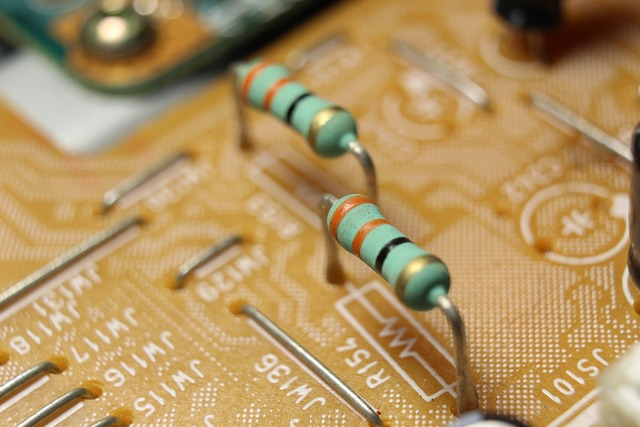

Carbon film resistors are the most common resistor and are easily recognizable by their cylindrical shape and color-coded bands.

They typically have four color bands, with the first two bands indicating the first two numbers of the resistance value. The third band indicates the number of zeroes to add to the first two digits to get the total resistance value. The fourth band is typically brown and indicates the tolerance or the precise resistance value.

Identifying Metal Film Resistors

Metal film resistors are similar in appearance to carbon film resistors but are more precise and have a lower tolerance. They also have identical color coding to carbon film resistors. The main difference between Metal film and Carbon film resistors is that metal film resistors have a negative temperature coefficient and higher precision.

Identifying Wire-Wound Resistors

A Wire-wound resistor is easily recognizable by its cylindrical shape and the fact that they are larger than other resistors. They also have a metal wire that is wound around the cylinder.

They are typically used for high-power applications and have a high resistance value. They usually have a color code, but the wire wound can also identify it.

Identifying Metal Oxide Film Resistors

Metal oxide film resistors are similar in appearance to carbon film light-dependent resistors but are more precise and have a lower tolerance. They also have identical color coding to carbon film resistors.

They are typically used in precision applications such as measurement equipment and signal processing circuits. The difference between the Metal oxide film and Carbon film resistors is that metal oxide film resistors have a lower temperature coefficient and higher precision.

Uses of Different Resistors

Resistors are widely used in electronic circuits to control the flow of electrical current, divide voltages, and provide bias to active devices such as transistors. They are also used with other components, such as capacitors and inductors, to filter and shape electrical signals. Additionally, they are used in power supplies to limit the current flow and, in safety, circuits to determine the current in case of a fault.

However, let’s look into specific uses of the most common resistors.

Uses of Carbon Film Resistors

Carbon film resistors are used in various applications, including audio equipment, power supplies, and digital circuits.

· RC Filter usage: They are also used as voltage dividers, current limiters, and RC filters.

· Current Limiting: Carbon film resistors can be used as current limiting resistors in power supply circuits to protect other components from damage.

· Snubber: Carbon film resistors can be used as snubber resistors in switching circuits to suppress high-frequency noise.

· Bias: Carbon film resistors can be used as bias resistors in amplifiers and oscillators to provide a stable DC bias to the circuit.

· Pull-up/Pull-down: Carbon film resistors can be used as pull-up or pull-down resistors in digital circuits to ensure correct logic levels.

· Automotive and Industrial: Carbon film resistors are also commonly used in automotive and industrial applications exposed to high temperatures and vibration.

Uses of Metal film resistors

Metal film resistors are used in precision applications such as measurement equipment and signal processing circuits.

· Audio Equipment: They are also used in audio equipment and power supplies. They are often used in applications where stability and precision are essential.

· Reference: Metal film resistors can be used as reference resistors in precision measurement circuits to provide a stable and accurate reference voltage.

· Feedback: Metal film resistors can be used as feedback resistors in operational amplifier circuits to provide negative feedback for stability and precision.

· Termination: Metal film resistors can be used as termination resistors in transmission line circuits to match the impedance of the transmission line to the load.

· Audio and Power: Metal film resistors are also used in audio equipment and power supplies.

· Medical Equipment: Metal film resistors are also often used in medical equipment or high-frequency circuits where stability and precision are essential.

Uses of Wire-wound resistors:

Wire-wound resistors are known for their high power handling capabilities and durability. Some other uses include:

· Industrial Application: They are also commonly used in industrial equipment and applications where resistance values above one ohm are needed.

· Load: Wire-wound resistors can be used as load resistors in power electronics circuits to dissipate excess power.

· Heating Element: Wire-wound resistors can be used as heating elements in industrial equipment and appliances.

· Damping: Wire-wound resistors can be used as damping resistors in oscillator circuits to dampen unwanted oscillations.

· Power Supplies: Wire-wound resistors are often used in power supply circuits, other high-power applications, and industrial equipment where stability and durability are essential.

Uses of Metal Oxide Film Resistors

Metal oxide film resistors are known for their stability and precision, similar to metal film resistors. Some other uses include:

· Precision: Metal oxide film resistors can be used as precision resistors in precision measurement circuits to provide a stable and accurate reference voltage. They are also used in audio equipment and power supplies. They are often used in applications where stability and precision are essential.

· Sensing: Metal oxide film resistors can be used as sensing resistors in temperature measurement circuits to provide a stable and accurate temperature reading.

· Potentiometer: Metal oxide film resistors can be used as potentiometers in electronic circuits to provide adjustable resistance for fine-tuning or adjustments.

· Audio and Power: Metal oxide film resistors are also used in audio equipment and power supplies.

· Medical Equipment: Metal oxide film resistors are also often used in medical equipment or high-frequency circuits where stability and precision are essential.

It is worth noting that these are not the only possible uses for each type of resistor but rather a selection of standard and relevant examples. In some cases, a combination of different fixed resistors may be used in a single application to achieve a specific performance.

It is essential to consider the application’s specific requirements and consult the datasheet of the resistors before making a final decision on the type of resistor to use.

Conclusion

Each of these types has its unique characteristics and uses. Understanding the differences between these types and their services is essential to select the correct resistor for a specific application.

By understanding the uses and characteristics of each type of resistor, you can make an informed decision and select the suitable resistor for your circuit.

Additionally, by learning to identify the different types of resistors by their visual characteristics or by measuring their resistance values, you can ensure that your circuit is built correctly and performs as intended.

Understanding the different types of resistors and their uses is essential to working with electronics. It will enable you to tackle any circuit design or repair project confidently.