Meta description

Learn everything you need to know about poly capacitors in this in-depth guide. Discover the types, benefits, installation, and troubleshooting tips for optimal performance.

Introduction

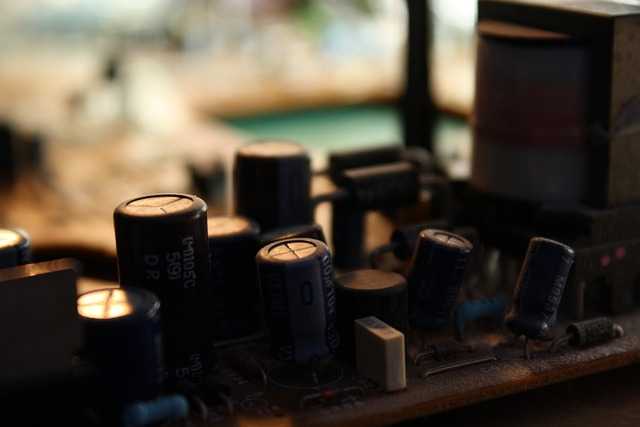

Capacitors are fundamental components in electronic circuits, serving various functions such as energy storage, filtering, and coupling. Poly capacitors have gained popularity among the various capacitors available due to their excellent electrical characteristics and versatility.

Poly capacitors are a type of capacitor that uses a polymer dielectric material to store charge. Compared to other types of capacitors, such as either ceramic capacitors or electrolytic capacitors, poly capacitors offer several advantages, including high capacitance values, low leakage current, and low dielectric absorption. They are widely used in power supplies, audio amplifiers, and RF circuits.

We will explore the different types of poly capacitors, how they work, the benefits they offer, installation considerations for optimal performance, and troubleshoot common issues that can occur.

What is a Poly Capacitor?

A poly capacitor, short for polyester capacitor, is an electronic component used in circuits to store and release electrical energy. It is made of a thin film of polyester, also known as Mylar, coated with a layer of metal on each side. The metal layers serve as the capacitor’s electrodes, which store charge between them.

Poly capacitors are known for their stability, reliability, and low cost. In addition to their use as decoupling capacitors, poly capacitors are also commonly used in audio amplifiers, power supplies, and RF circuits. Depending on the specific application requirements, they can be found in various sizes and capacitance values.

Poly capacitors are often used with other types, such as ceramic or electrolytic capacitors, to achieve specific capacitance values and performance characteristics.

Working of Poly Capacitor

The working principle of a poly capacitor is based on the ability of a dielectric material, in this case, polyester, to store an electric charge between two conductive plates. The electrons accumulate on one plate when the voltage is applied, creating a negative charge, while the other plate becomes positively charged. This creates an electric field across the dielectric material.

Several factors, including the area of the plates, the distance between the plates, and the polyester film’s dielectric constant, determine the poly capacitor’s capacitance. The dielectric constant, known as the relative permittivity, measures how well the material can store an electric charge.

Poly capacitors have a shallow leakage current, meaning they can hold their charge long without losing it. They also have low dielectric absorption, so they can quickly discharge when a voltage is applied, making them ideal for applications where fast charging and discharging are required.

Poly capacitors are simple and reliable components widely used in electronic circuits to store and release electrical energy, providing a stable and efficient power source.

Materials Used in Poly Capacitors

The dielectric materials used in poly capacitors are typically one of the following types of plastic films:

Polyester (PET):

PET capacitors are known for their small size, low cost, and good temperature stability. They offer moderate capacitance values and higher voltage out ratings, making them suitable for general-purpose applications.

Polypropylene (PP):

PP capacitors are valued for their low dielectric losses, high insulation resistance, and excellent temperature stability. Due to their low dissipation factor, they are widely used in high-voltage and frequency applications.

Polycarbonate (PC):

PC capacitors offer high dielectric strength, low dielectric absorption at high voltages, low voltage circuits, and good temperature stability. However, they are less common than PET and PP capacitors due to their higher cost and limited availability.

Polyethylene Naphthalate (PEN):

PEN capacitors have higher temperature stability and better electrical characteristics than PET capacitors, making them suitable for high-temperature applications.

Polyphenylene Sulfide (PPS):

PPS capacitors exhibit excellent temperature stability, low dielectric losses, and high insulation resistance. They are well-suited for high-frequency and high-temperature applications.

Benefits of Poly Capacitors

Poly or polyester capacitors offer several benefits, making them popular for various electronic applications. Some of the critical benefits of poly capacitors include the following:

Stability:

Poly capacitors have a high stability level, meaning their capacitance value remains consistent over time and under varying environmental conditions, such as temperature and humidity.

Low Cost:

Polyester is inexpensive, making poly capacitors a cost-effective option for many electronic applications.

Low Leakage Current:

Poly capacitors have a shallow leakage current, which means they can hold their charge for long periods without losing it, making them ideal for long-term energy storage applications.

Fast Charge and Discharge:

Poly capacitors have low dielectric absorption, so they can quickly charge with electric current and discharge when a voltage is applied. This makes them ideal for applications that require fast charging and discharging.

Wide Range of Capacitance Values:

Poly capacitors are available in various capacitance values, making them suitable for various electronic applications, including decoupling, filtering, timing, and power supply applications.

Poly capacitors are reliable, cost-effective, and widely used in electronic circuits due to their stable performance, low leakage current, and fast charge and discharge characteristics.

Why should you consider using Poly Capacitors in your projects?

Poly or polyester capacitors are an excellent choice for many electronic projects due to their stable performance, low cost, and wide range of capacitance values.

Cost-effective:

Polyester is inexpensive, making poly capacitors a cost-effective option for many electronic projects.

Stable performance:

Poly capacitors have a high stability level, meaning their total capacitance and value remains consistent over time and under varying environmental conditions.

Low leakage current:

Poly capacitors have a low and no leakage current, which means they can hold their charge for long periods without losing it, making them ideal for applications requiring long-term energy storage.

High reliability:

Poly capacitors have a long service life and are highly reliable, making them suitable for various electronic applications.

Fast charge and discharge:

Poly capacitors have low dielectric absorption, so they can quickly charge and discharge when a voltage is applied, making them ideal for applications that require fast charging and discharging.

Wide range of capacitance values:

Poly capacitors are available in various capacitance values, making them suitable for various electronic applications, including decoupling, filtering, timing, and power supply applications.

Poly capacitors are an excellent choice for many electronic projects due to their stable performance, low cost, high reliability, fast charge and discharge characteristics, and wide range of capacitance values.

Different Types of Poly Capacitors

There are several types of poly capacitors, each with unique characteristics that make them suitable for different electronic applications.

Metalized Polyester Film Capacitors:

These capacitors are made by depositing a thin metal layer on both sides of a polyester film. They offer excellent stability and low cost and are ideal for high-frequency applications like filtering, timing, and coupling.

Polypropylene Capacitors:

Polypropylene capacitors are made of polypropylene film and are known for their excellent electrical properties and low losses. They are ideal for high-precision applications like audio equipment and high-frequency circuits.

Polycarbonate Capacitors:

Polycarbonate capacitors are made of polycarbonate film and offer excellent temperature stability, low losses, and high insulation resistance. They suit various applications, including power supply filters, full DC blocking, and coupling.

Polyphenylene Sulfide (PPS) Capacitors:

PPS capacitors are made of a polyphenylene sulfide film and are known for their high-temperature resistance, stability, and reliability. They are commonly used in applications requiring high-temperature stability, such as automotive and industrial electronics.

Polyester/Polypropylene Capacitors:

These capacitors are made by combining polyester and polypropylene films to create a hybrid capacitor that offers the benefits of both materials. They suit various applications, including audio equipment, power supply filters, and timing circuits. dec

Installation Considerations of Poly Capacitors

Proper installation and configuration are essential for ensuring optimal performance and reliability of poly capacitors. Here are some considerations for installing and configuring a poly capacitor:

Polarization:

Some poly capacitors, such as metalized polyester film capacitors, are polarized and must be installed with the correct polarity to avoid damaging the film capacitor or causing circuit malfunctions. Check the datasheet or markings on the capacitor to ensure proper polarity during installation.

Voltage Rating:

Choose a poly capacitor with a voltage rating that exceeds the maximum voltage that will be present in the circuit. Exceeding the capacitor’s voltage rating can cause it to fail, resulting in circuit damage or malfunction.

Temperature Rating:

Choose a poly capacitor with a temperature rating appropriate for the expected operating temperature range of the circuit. Exceeding the temperature rating of the capacitor can cause it to fail or lose its capacitance value.

Mounting:

Mount the capacitor securely to prevent movement or vibration, which can cause damage or affect performance.

Placement:

Consider the location of the capacitor in the circuit to minimize the length of the connecting leads and avoid placing the capacitor near sources of heat, electromagnetic interference working voltage or other sources of interference.

Filtering:

In applications requiring filterings, such as power supplies or audio circuits, consider the circuit’s capacitance value and frequency response to select the appropriate poly capacitor.

Circuit Configuration:

Poly capacitors can be used in various circuit configurations, such as series, parallel, or network. Consider the desired capacitance value, voltage rating, and other factors when selecting the appropriate configuration for the application.

In summary, proper installation and configuration are essential for ensuring optimal performance and reliability of poly capacitors. When selecting and installing poly capacitors in your electronic projects, consider factors such as polarization, voltage rating, temperature rating, mounting, placement, filtering, and circuit board configuration.

Troubleshooting Common Issues

Poly capacitors are generally reliable and robust components, but like any electronic component, they can occasionally fail or experience problems. Here’s how you can troubleshoot them:

Capacitance Drift:

Over time, poly capacitors can experience a change in capacitance value, which can affect the circuit’s performance. To troubleshoot capacitance drift, measure the capacitance value of the capacitor using a capacitance meter and compare it to the expected value listed on the datasheet. If the measured capacitance value is significantly different from the expected value, the capacitor may need to be replaced.

Short Circuits:

A short circuit can occur when the dielectric material inside the capacitor breaks down, allowing the electrodes to come into contact. To troubleshoot a short circuit, use a multimeter to test the resistance of the capacitor. If the resistance is very low or zero, the capacitor is likely shorted and needs to be replaced.

Open Circuits:

An open circuit can occur when the capacitor fails to contact the electrodes and the leads, usually due to a faulty connection. To troubleshoot an open circuit, use a multimeter to test the continuity of the capacitor leads. If there is no continuity, the capacitor may be faulty and needs to be replaced.

Voltage Leakage:

Voltage leakage can occur when the dielectric material in a polarized capacitor breaks down, allowing current to flow through the capacitor. To troubleshoot voltage leakage, measure the voltage across the capacitor when it is not connected to the voltage source in the circuit. If the voltage does not discharge or takes a long time, the capacitor may be faulty and must be replaced.

Overheating can occur when the capacitor is exposed to excessive heat or current. To troubleshoot overheating, check the temperature rating of the capacitor and ensure that it is not being used beyond its rated capacity. If the capacitor is being used within its rated capacity and still overheating, it may be inaccurate and need to be replaced.

In summary, troubleshooting common issues with poly capacitors involves testing the capacitance value, resistance, continuity, and voltage leakage of the capacitor using a multimeter, checking the temperature rating, and ensuring that the capacitor is not being used beyond its rated capacity. If the capacitor is faulty, it may need to be replaced.

Best Practices for Maintaining Poly Capacitors

Poly capacitors are reliable components, but proper maintenance can help ensure optimal performance and longevity. Here are some best practices for maintaining poly capacitors:

Avoid Overvoltage:

Poly capacitors have a maximum voltage rating, and exceeding this dc voltage rating can cause the capacitor to fail or lose its capacitance value. Be sure to select a capacitor with a voltage rating that exceeds the maximum voltage that will be present in the circuit and avoid applying voltage beyond the rated capacity of a specific capacitor.

Avoid Overheating:

Poly capacitors can be damaged by excessive heat, which can cause the dielectric material to break down or the capacitance value to drift. Avoid exposing poly capacitors to high temperatures and ensure they are not being used beyond their rated temperature range.

Avoid Mechanical Stress:

Poly capacitors can be damaged by mechanical stress, which can cause the dielectric material to crack or the capacitor to fail. Mount the capacitor securely to prevent movement or vibration, and avoid bending or twisting the leads during installation.

Avoid Moisture:

Poly capacitors can be damaged by moisture, which can cause the dielectric material to break down or the ceramic capacitor itself to corrode. Store poly capacitors in a dry environment and avoid exposing them to moisture or humidity.

Inspect for Damage:

Inspect poly capacitors regularly for signs of damage, such as cracks, bulges, or discoloration. If a capacitor appears damaged, replace it immediately.

Avoid Excessive Current:

Poly capacitors can be damaged by excessive current, which can cause the dielectric material to break down or the capacitor to overheat. Be sure to select a capacitor with a current rating that exceeds the maximum current that will be present in the circuit.

Choose Quality Components:

Choose high-quality poly capacitors from reputable manufacturers to ensure reliability and performance.

In summary, maintaining poly capacitors involves avoiding overvoltage, overheating, mechanical stress, moisture, and excessive current, inspecting for damage regularly, and choosing quality components. Following these best practices can ensure optimal performance and longevity of poly capacitors in your electronic projects.

Conclusion

In conclusion, poly capacitors are an essential component of many electronic circuits, and understanding their properties and applications is critical to ensuring optimal performance and reliability. Following the best practices for maintaining and troubleshooting poly capacitors, you can avoid common issues and keep your circuits running smoothly.